Waste to Energy

Plasma gasification in waste to energy

Plasma gasification in waste to energy is one of the novel applications that were introduced many years ago. Landfill sites and incineration continue to be the primary methods used to dispose of wastes with significant negative impact on the environment. Landfill releases methane which is 21 times more dangerous as a greenhouse gas than carbon dioxide. Incineration is often pushed as an alternative to land filling. However, it is a known fact that incinerator ashes are contaminated with heavy metals, unburned chemicals and new chemicals formed during the burning process.

These ashes are then buried in landfill or dumped in the environment. Rather than making waste disappear, incinerators create more toxic waste that pose a significant threat to public health and the environment. Sustainable and successful treatment of municipal solid waste (MSW) should be safe, effective, and environmentally friendly.

We build more than projects; we help progress society through economic development. Establishing a shared vision with customers and stakeholders, we deliver customized initiatives that help transition local content programs toward long-term economic development.

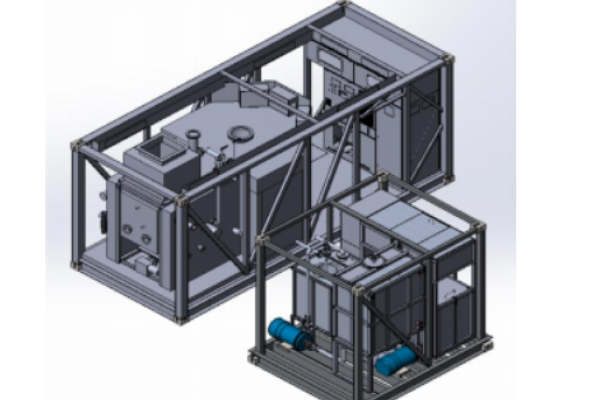

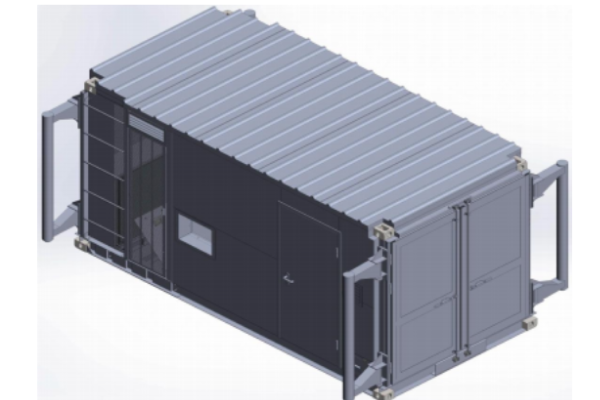

The mobile plasma gasification unit is designed as a single Monoblock unit with equipment for loading waste, a plasma reactor and a chamber for plasma cracking of synthesis gas, removal, cooling and purification of generated synthesis gas, to which industrial plasma system with arc agitators (oscillators), steam generators, steam superheaters, and plasma torches are connected.

The container has a fully welded metal framing design and is sheathed with mineral-cotton sandwich panels. This ensures the required durability and protection from external weather factors for the module which allows using the module outdoors without a special shelter. The container can be lifted and moved using a lifting gear by means of hooking the cross-beams. It is possible to create an automatically unloaded container.

The product is supplied in assembled condition; external utilities are to be assembled in according to the design documents. All components of the unit are fitted with instrumentation and automation means and a distributed and unified information display system.

Option for transporting the plasma gasification unit and/or option for a mobile plasma unit that is constantly transported and operated on a truck chassis:

1) Plasma unit on container trailers of a semitrailer tractor

2) Container of the plasma gasification unit with a hydraulic system for automatic loading / unloading from truck trailers

Estimation for a Minimum Capacity Plant (Single Module)

| Item | Quantity/Container | Formula |

|---|---|---|

| waste plasma gasification unit (4 tons per day) | 1 | 150 kg per hour |

| Net Electricity Generation (kg per hour of municipal solid waste) | 1.5 kW per hour |

Estimation for a Maximum Capacity Unit (Single Module)

| Item | Quantity/Container | Formula |

|---|---|---|

| waste plasma gasification unit (25 tons per day) | 1 | 1000 kg per hour |

| Net Electricity Generation (kg per hour of municipal solid waste) | 1.5 kW per hour |

Estimation for a Multi module Facility (52,500 tons per year (150 tons per day)) 3)

| Item | Quantity/Container | Formula |

|---|---|---|

| Waste plasma gasification unit (25 tons per day) | 6 pcs. | |

| Electric and heat energy generating unit | 15-20 MW per hour |

Estimation for a Multi module Plant (87,500 tons per year (250 tons per day)):

| Item | Quantity/Container | Formula |

|---|---|---|

| Waste plasma gasification unit (25 tons per day) | 10 pcs. | |

| Electric and heat energy generating unit | 20-30 MW per hour |

Estimation for a Multi module Plant (175,000 tons per year (500 tons per day))

| Item | Quantity/Container | Formula |

|---|---|---|

| Waste plasma gasification unit (25 tons per day) | 20 pcs. | |

| Electric and heat energy generating unit | 40-60 MW per hour |

About Us

We specialise in the profitable delivery of renewable energy and infrastructural projects.

Useful Links

Our Contacts

GT-033-5422,

Spintex, Greater Accra, Ghana.